What is a Flexible Filament?

First Print

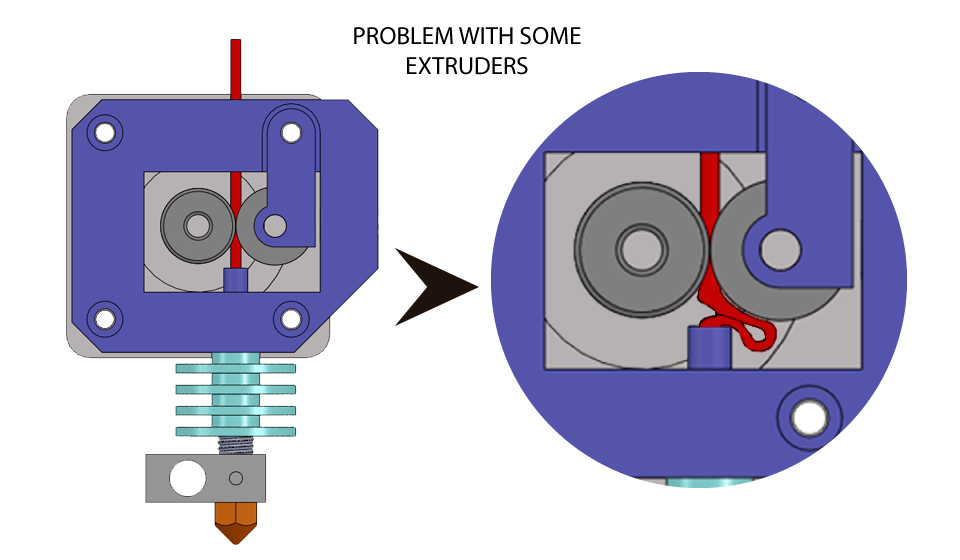

Problem #1 - Unconstrained Filament

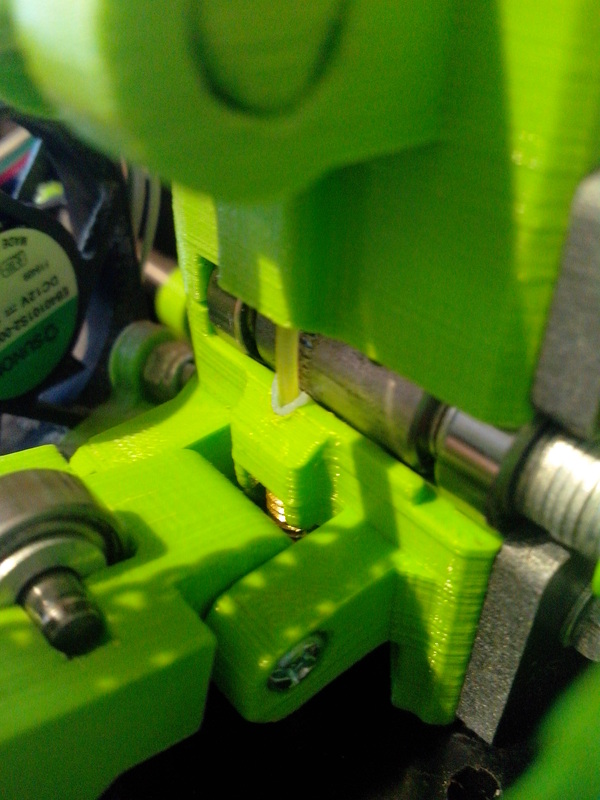

Even a small gap can have issues :

There are several ways to achieve this and your individual extruder may vary and it may/may not be possible to achieve on some printers.

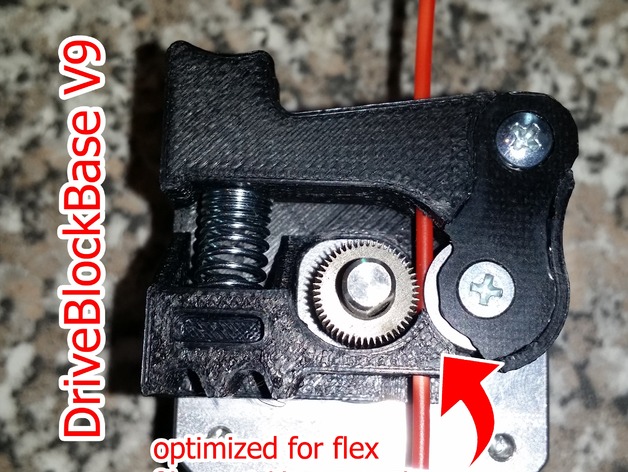

1. Retrofit an extra support insert into the extruder.

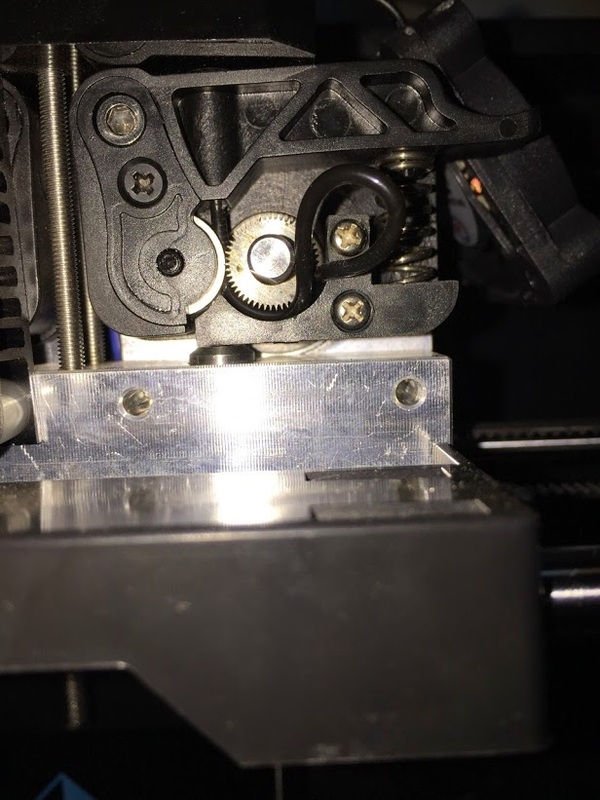

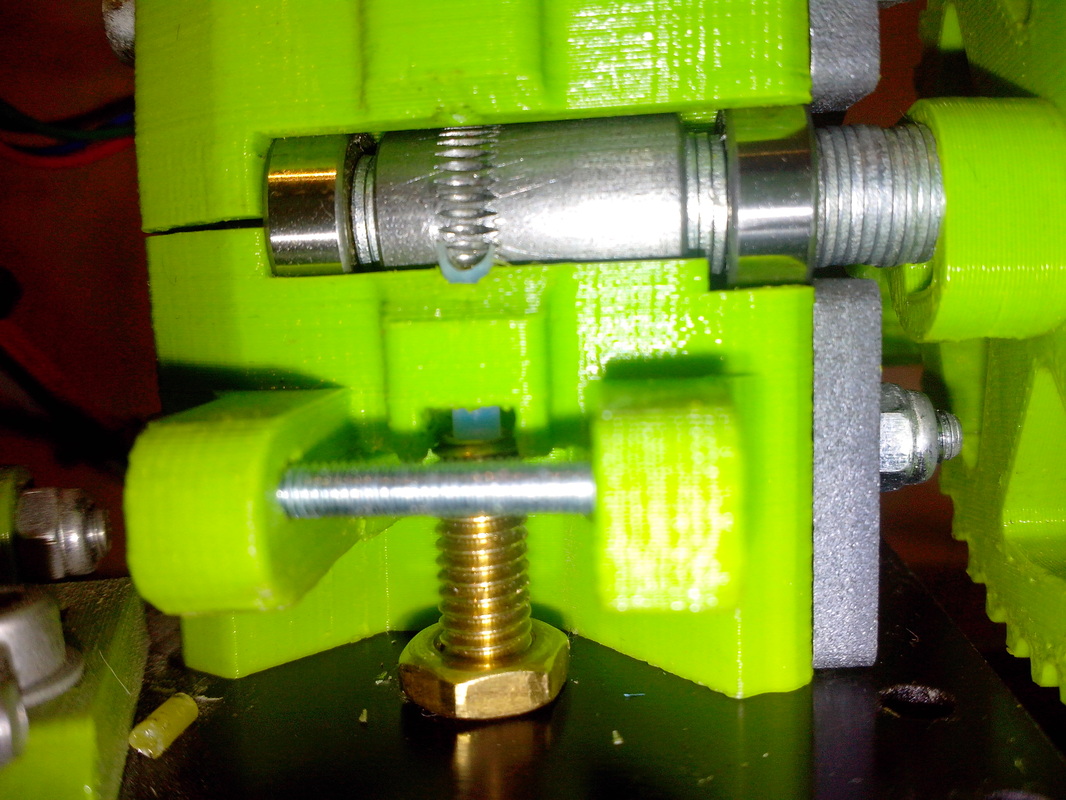

An example of retrofit supports :

- Second filament guide for Jigsaw extruder

- Printrbot Simple V2 flexible filament guide

- V9 Extruder Filament Guide 1,75mm

There are many of these upgrades including several I have designed myself as part of "Gyrobot's Extruder Week":

And another alternative :

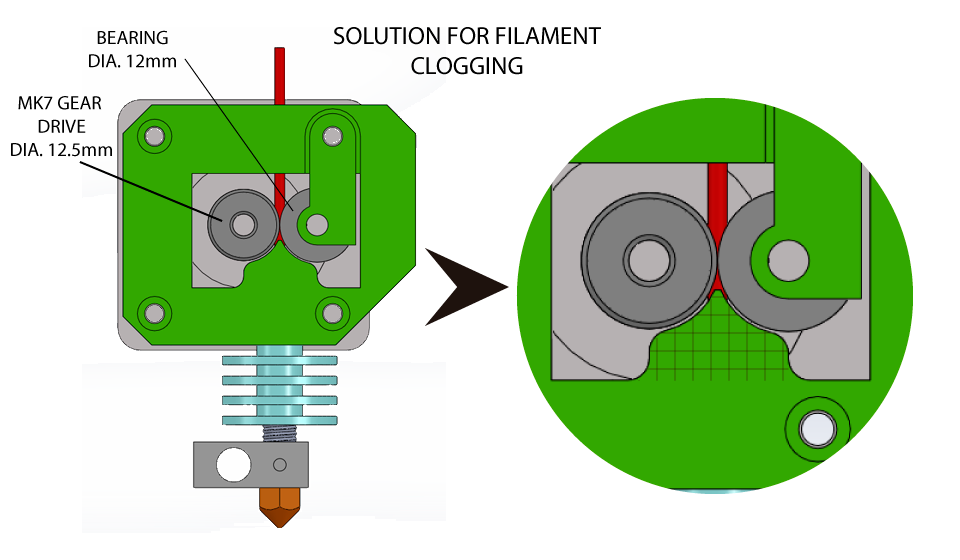

Solution #1

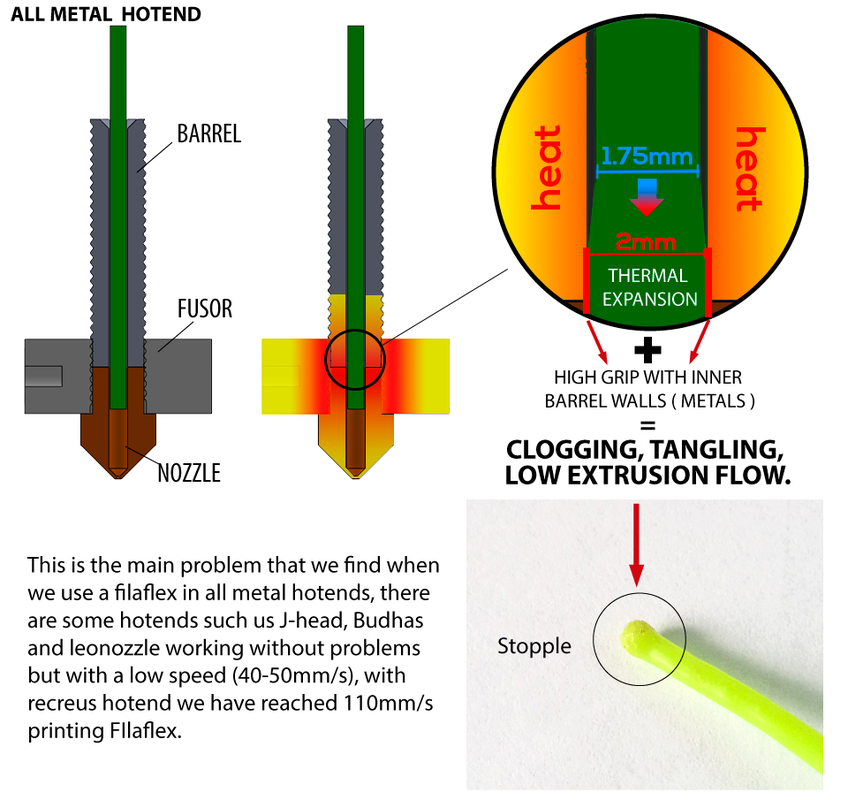

Problem #2 - Friction

Solution #2

If possible, feed the flexible filament directly into the Extruder, without a using a feed tube. Ideally from above at a height of 12” or more from the printer, the higher the better. This will provide an unrestricted path, with gravity on your side. If you have to use a feed tube, make sure it is PTFE (low friction) rather than Silicon, fuel line or pneumatic pipe etc. Avoid any sharp turns or kinks in the tube, and allow the filament to enter the tube as straight as possible. It is unfortunate that that latest generation of some popular printers have the most convoluted path you could probably imagine.

After the Drive gear

- Keep this length as short as possible to the hot end. Pushing a flexible filament into a hot end will result in compression and it’s diameter will increase as a result. Couple this with the thermal expansion of the filament inside the hot end and the pressure increases, miss feeds are the result. A Bowden style extruder are most problematic for this reason. I would suggest mounting the drive extruder above the printer rather than off to the side or rear, gravity will help in this case. Also for Bowden, as above, use a PTFE feed tube, and is also best with a 3mm diameter filament for fasted printing speeds, 1.75mm will work, again much slower though.

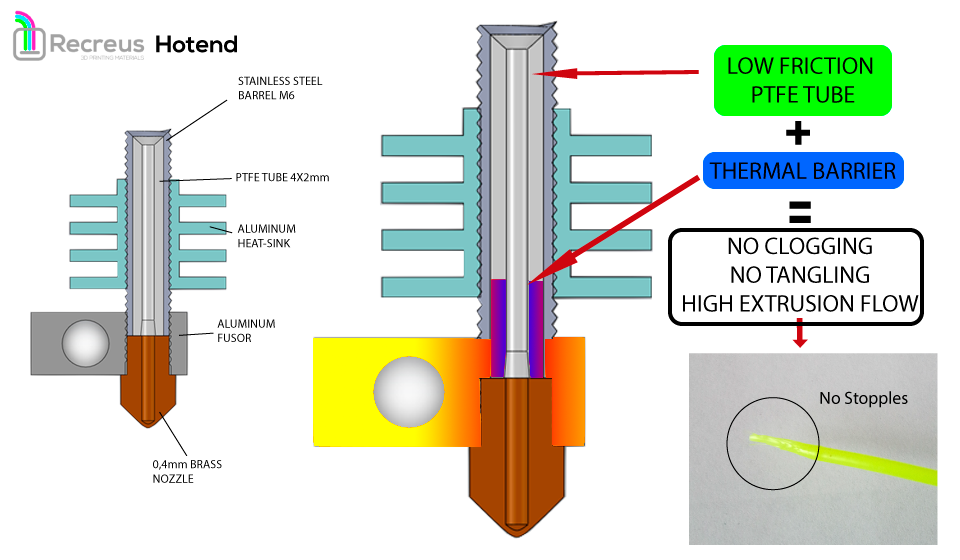

- Insert a PTFE liner into the hot end barrel to reduce the thermal expansion problem :

Problem #3 - Hotend Pressure

Solution #3

- I have tried nozzles 0.2mm, 0.3mm, 0.4mm and 1mm and the 1mm nozzle certainly throws out the filament as you would expect, and you can ramp the speed up. A 1mm nozzle can actually still print pretty good quality prints, because the Z layer height can still be set low, say 0.3mm. The extrudate will be squashed flatter and you will loose detail on some complicated perimeters, but the Z resolution will still be good. A 0.4mm nozzle is a good compromise for XY quality and speed.

- Cool the barrel. The smaller the melt zone and the closest it is to the nozzle the better. A fan blowing on the upper part of the barrel and over the general extruder area will keep this cool and help reduce any premature softening of the filament as it travels down the barrel. If the filament gets soft too soon then it can buckle easier and expand to grip the side walls of the PTFE liner.

- Increase the temperature. The hotter the temperature of the hot end, the runnier the extrudate becomes therefore the flow is easier. 240deg is a common ceiling for this material before you may start noticing a bit of boiling occurring. If the filament starts to boil, the print will have a "foamy" look about it, which can actually still look quite good. Because the thermodynamics of various heater/thermistor hot-end combos are so different, it is difficult to tell you what exact temperature to print at. Try turning up the temperature and do some test prints, once you start noticing the material boiling, then back off 5°C

Final Word

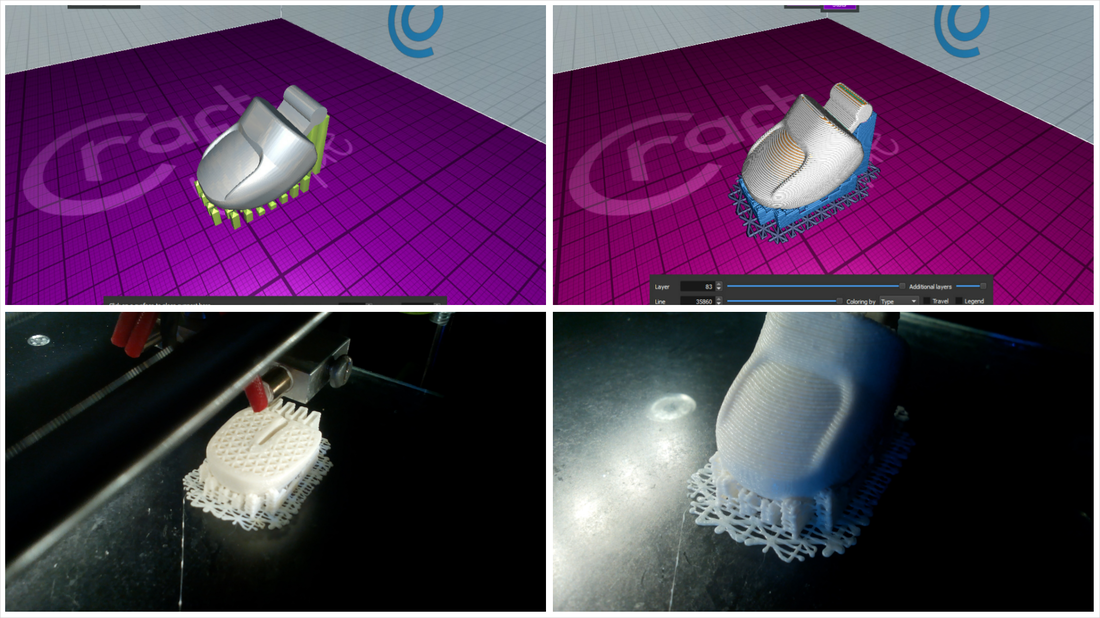

For me, my slicer of choice is Craftware by Craftunique. It seems to print flexible filament with the default settings, I just had to set the nozzle size (strangely called extrusion width) to my default 0.4 and reduce the speed accordingly, I also set the retract length to 4mm. It also has a great customisable support facility, which consists of pillars which can be added/removed/resized/auto generated before slicing, even placed on angles branching out like a tree. The support is easily removable, even with flexible filaments such as this Filaflex thumb below. It has super fast slicing, great graphics and is free, check it out :

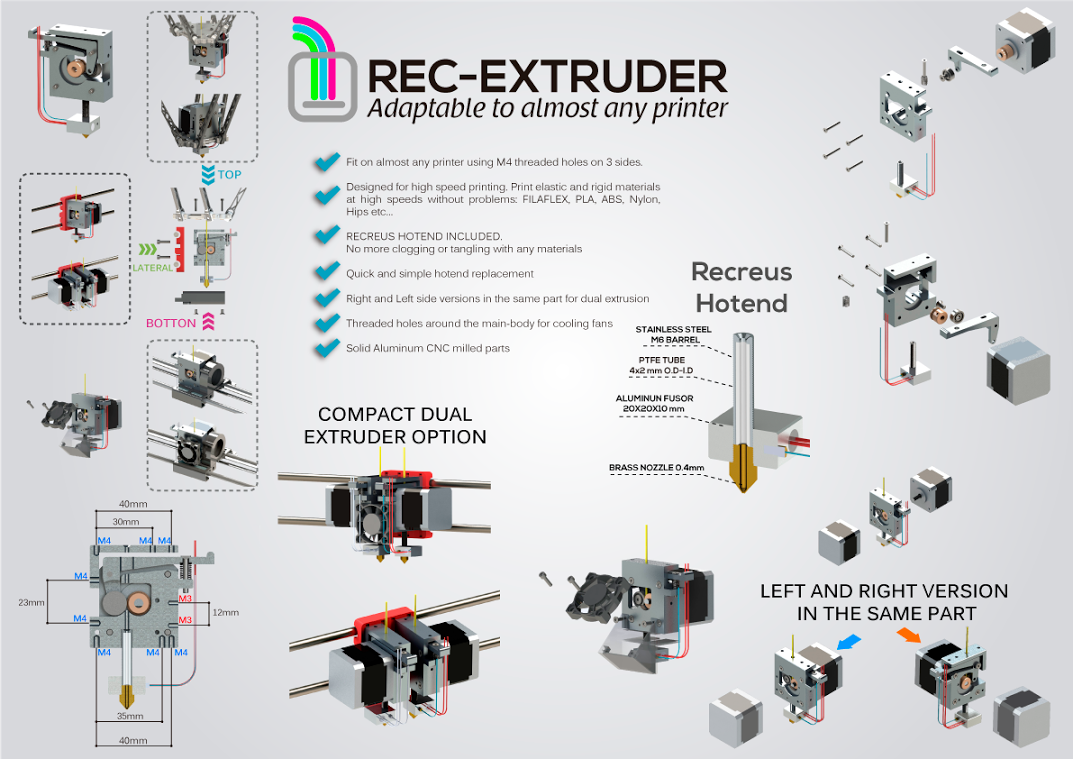

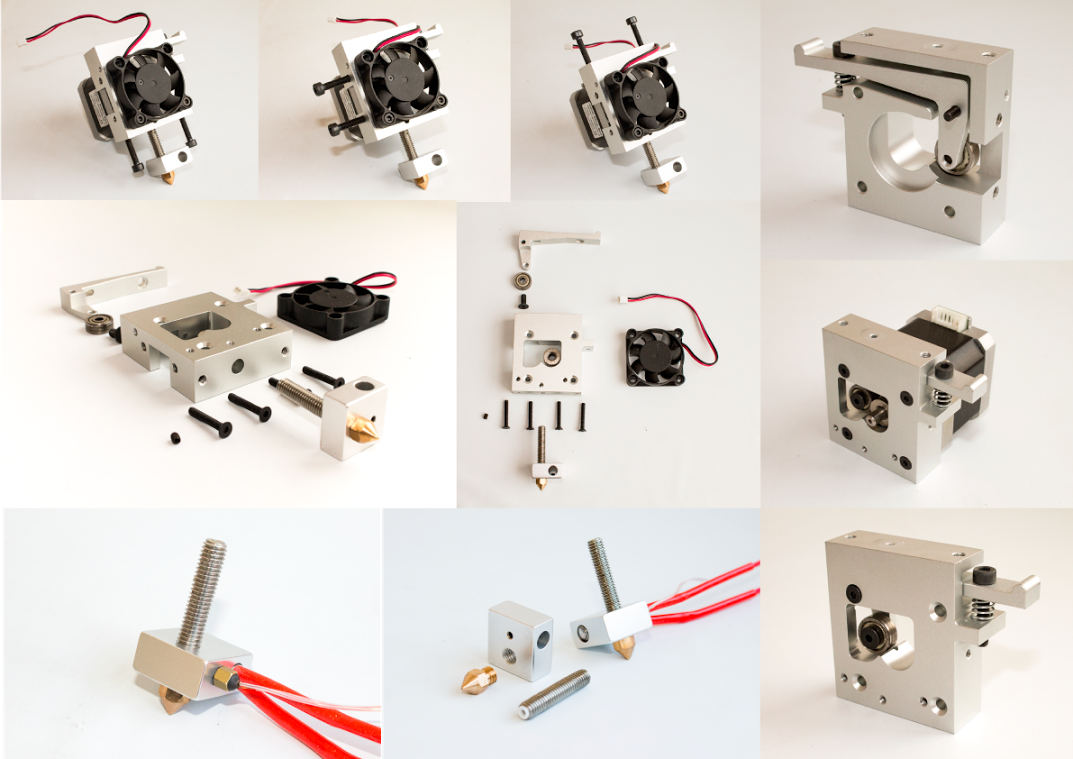

If you are building your own printer or manufacturing printers, then consider the Recreus Extruder and Hotend combo which is due out at beginning of November 2014, It's a plug and play approach with many mounting holes on all sides so it is very adaptable. You will then be able to print with PLA, Filaflex and ABS at high speeds.

I would like to take this opportunity to thank Recreus for the use of some images to help me explain the problems and solutions.

There are also many solutions on Thingiverse for you to print off your own upgrade. Maybe it's just a case of tweaking your hot end or slicer settings.

RSS Feed

RSS Feed