It has been a long time since my last post on 3D printed insoles or indeed any other subject, but there is good reason.

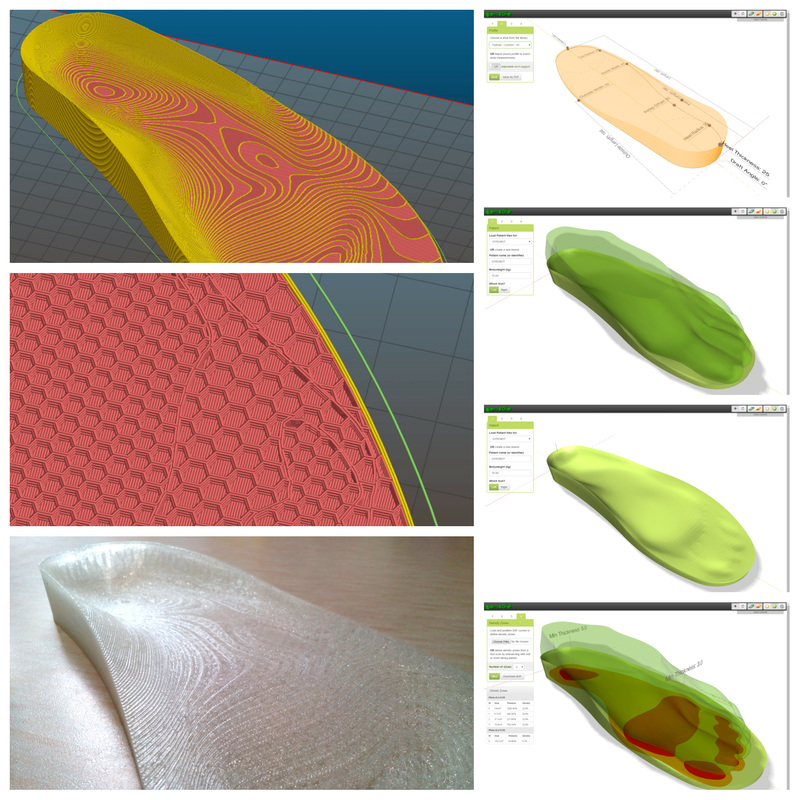

Over the past year I have taken all I know (insert joke here) on designing and 3D printing insoles and packaged that up into a mostly all-in-one piece of software called Gensole®.

What is Gensole?

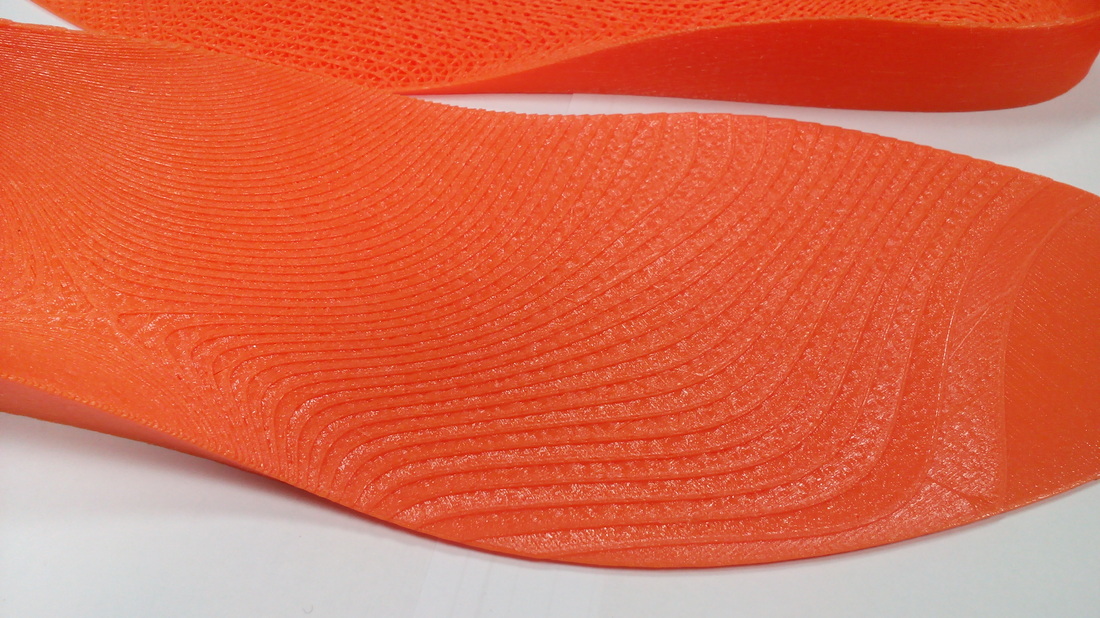

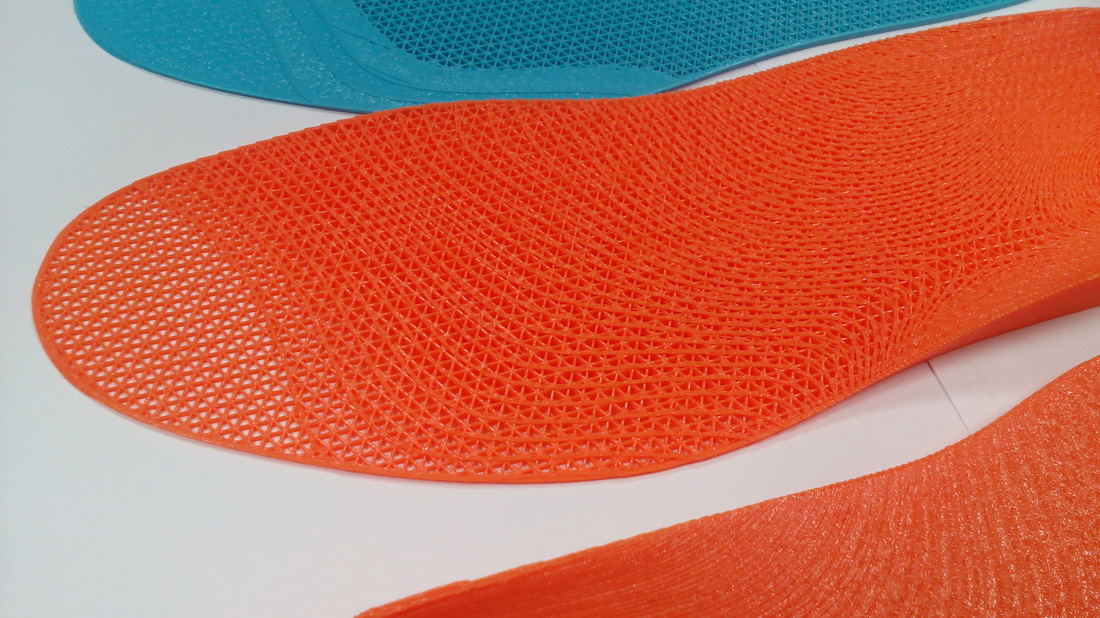

Gensole is a browser based tool which allows you to design insoles, optimised for 3D printing using the FDM process and Filaflex (TPE/TPU) type materials. It will ultimately export .AMF files for importing into Slic3r for 3D printer toolpath creation.

It is free for makers, and researchers for non-commercial use :

Over the past year I have taken all I know (insert joke here) on designing and 3D printing insoles and packaged that up into a mostly all-in-one piece of software called Gensole®.

What is Gensole?

Gensole is a browser based tool which allows you to design insoles, optimised for 3D printing using the FDM process and Filaflex (TPE/TPU) type materials. It will ultimately export .AMF files for importing into Slic3r for 3D printer toolpath creation.

It is free for makers, and researchers for non-commercial use :

RSS Feed

RSS Feed