Part 3 - Variable Density Insole

...Continued from Part 2 - Open Core Mesh

It is now where we start to see a major advantage of 3D printing over existing insole technology. The traditional method to make a custom formed insole is to CNC machine the insole out of a solid block of a suitable chosen hardness of material. Post machining modifications can be implemented by added inserts in different materials etc. Any operation that requires multiple steps is adding to the complexity, inventory of different material stocks, skills and of course cost.

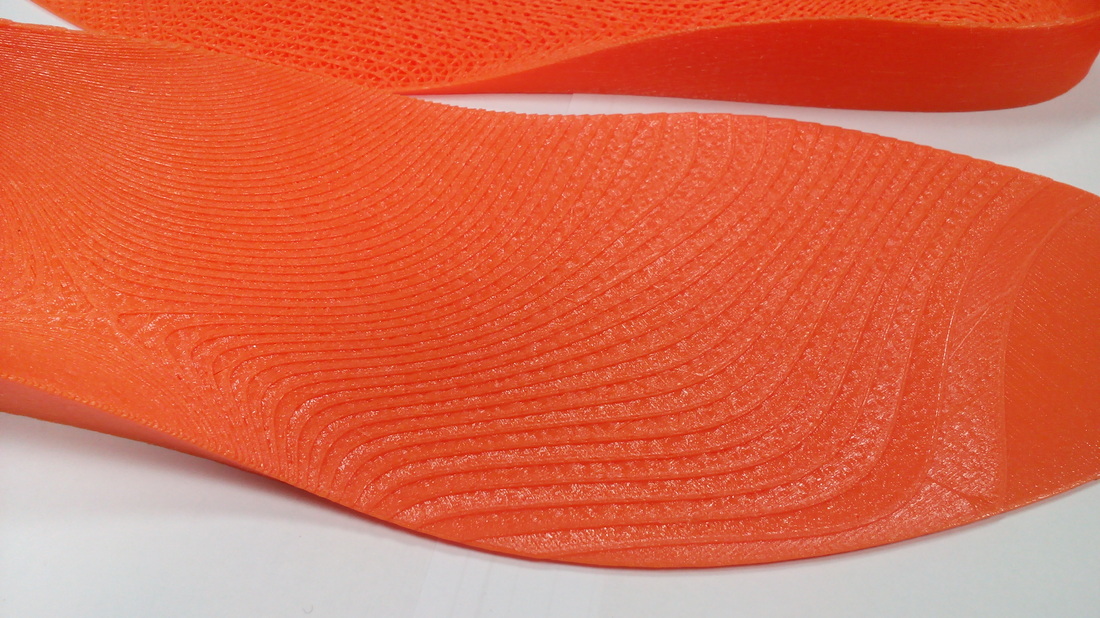

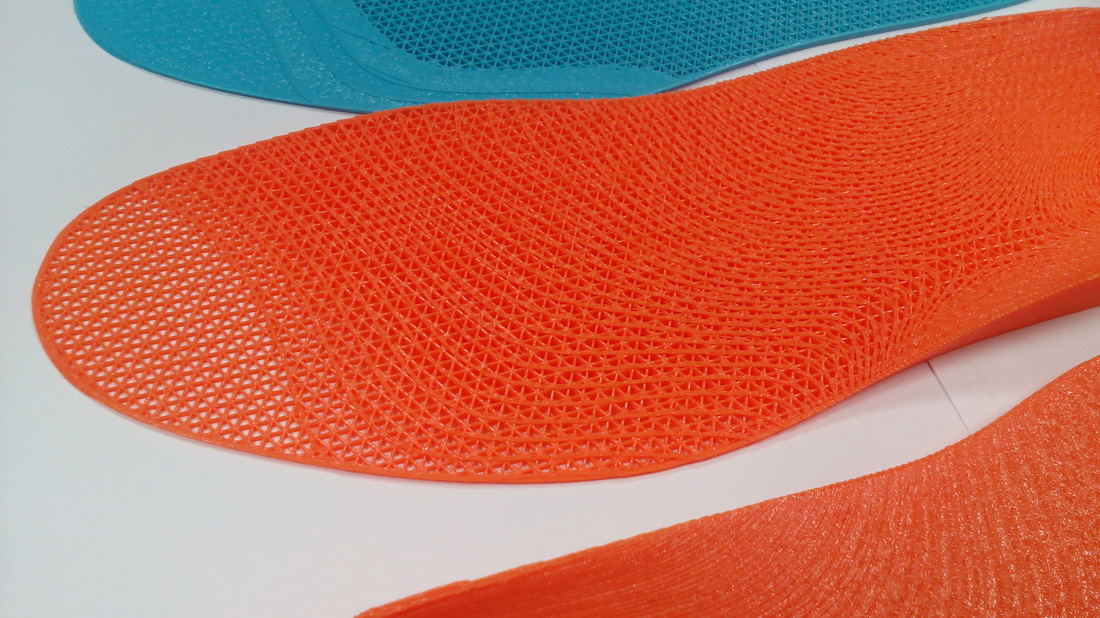

Here we can see that for a single use of material and machine (3D printer), a complex structure of insole can be created with differing grades of hardness according to the recipients needs.

It is now where we start to see a major advantage of 3D printing over existing insole technology. The traditional method to make a custom formed insole is to CNC machine the insole out of a solid block of a suitable chosen hardness of material. Post machining modifications can be implemented by added inserts in different materials etc. Any operation that requires multiple steps is adding to the complexity, inventory of different material stocks, skills and of course cost.

Here we can see that for a single use of material and machine (3D printer), a complex structure of insole can be created with differing grades of hardness according to the recipients needs.

RSS Feed

RSS Feed