Part 3 - Variable Density Insole

It is now where we start to see a major advantage of 3D printing over existing insole technology. The traditional method to make a custom formed insole is to CNC machine the insole out of a solid block of a suitable chosen hardness of material. Post machining modifications can be implemented by added inserts in different materials etc. Any operation that requires multiple steps is adding to the complexity, inventory of different material stocks, skills and of course cost.

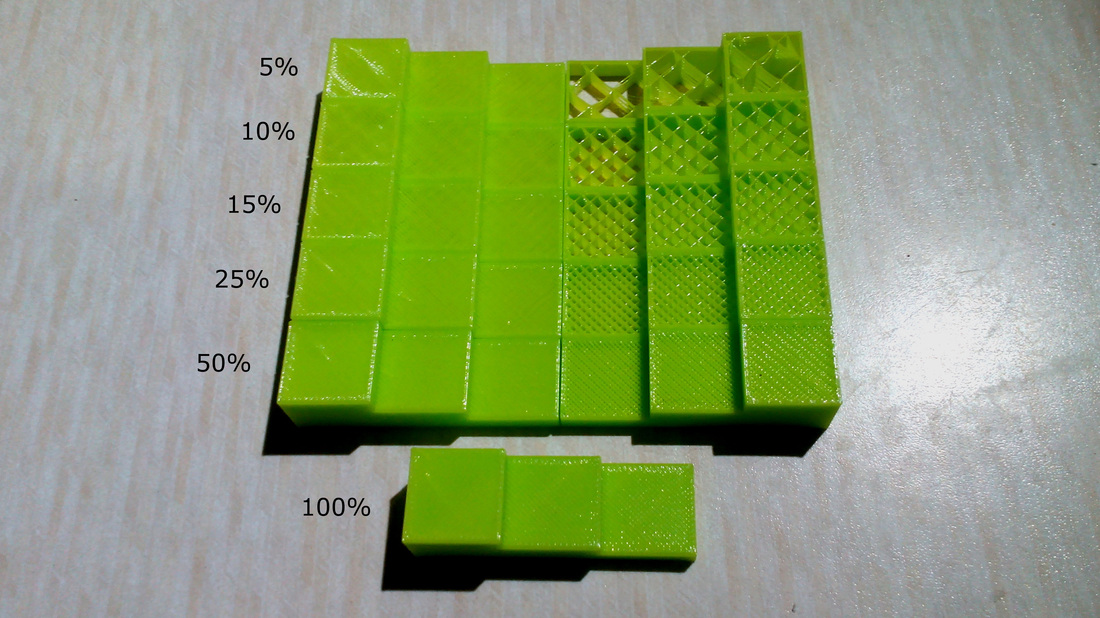

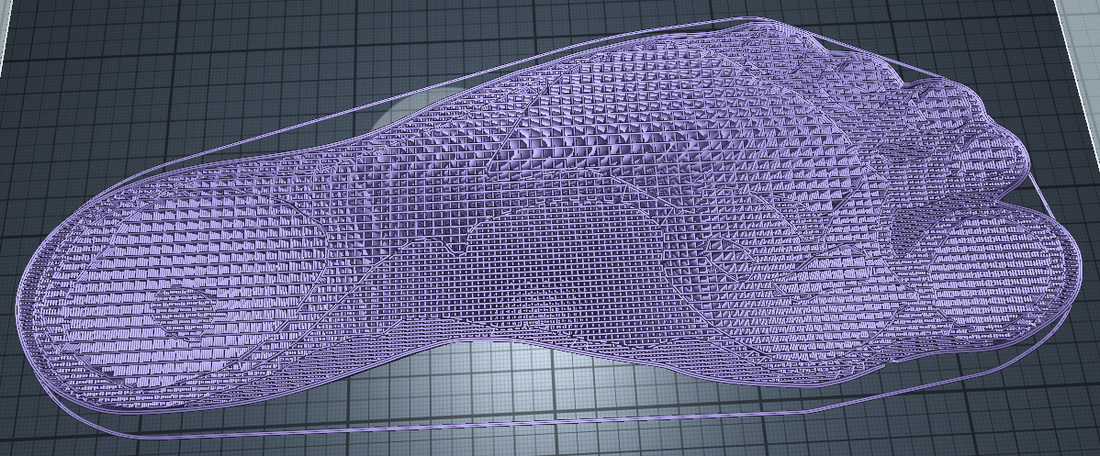

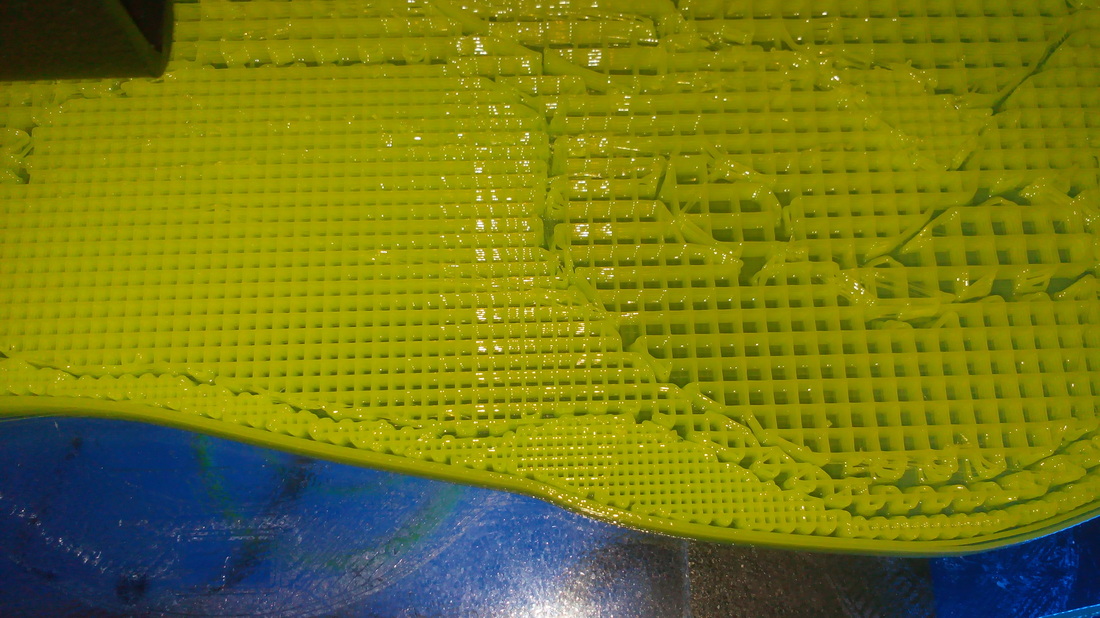

Here we can see that for a single use of material and machine (3D printer), a complex structure of insole can be created with differing grades of hardness according to the recipients needs.

The example above is a completely uniform 10mm thick for no other reason than to show you when holding it up to the light, you can see the variation of the density without any thickness changes distorting the light pattern.

My example stl files and Slic3r setting files can be downloaded from Thingiverse.

Note : Slic3r version used 1.1.7

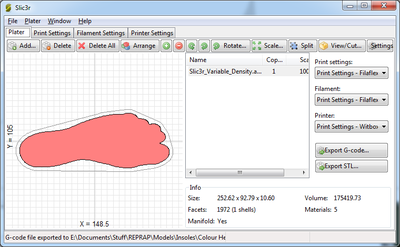

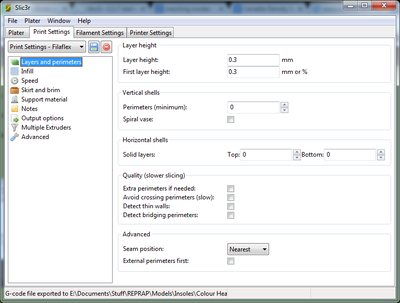

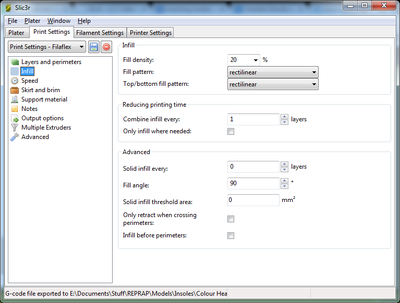

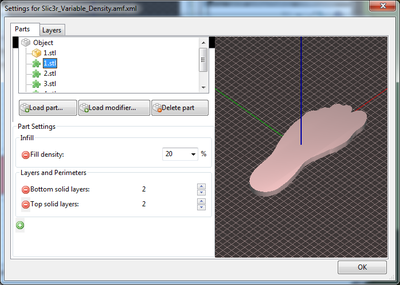

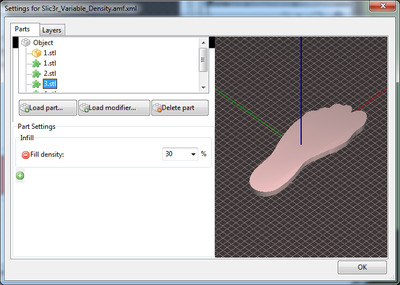

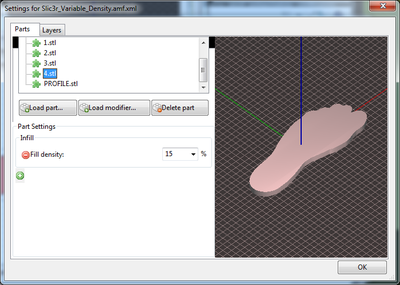

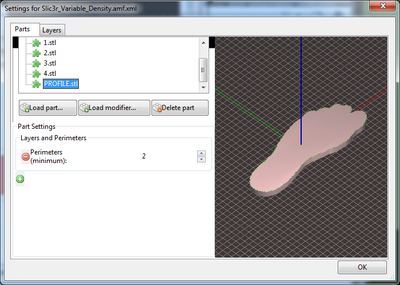

If you import my Config Bundle and .amf file (Additive Manufacturing File) into Slic3r then the following settings are defined for you, allowing you to export gcode straight away.

How to Programme Variable Densities in Slic3r

If all goes well, you should have some G-code that you can print with, you can check mine out here.

So far, I have purposely stayed away from the techniques and procedures involved in the image and CAD side for simplicity until the next article. The free opensource tool chain used will be Gimp, Inkscape and finally OpenSCAD to create the CAD models. The result will offer "Form Fitting" variant too.

The disclaimer here is that I am only providing information, this is not medically certified and is not designed to be such, but hey in many parts of the world, people walk round on planks of wood or old car tyres so everything is builder beware. Go forth and MAKE!!!

RSS Feed

RSS Feed